We’ve been hearing a lot about virtual reality technology, especially in the video games industry, but this impressive breakthrough is still making a lot of noise in many other areas. This VR has, in fact, a great future ahead of it. In the medical field as we all know but also in the manufacturing industry. Potentials have been affirmed over time and it’s up to us to exploit them. Did you know that virtual reality brings many solutions to companies at different levels such as conception, pre-production, and problem-solving? Although this technology is continuously developing, let’s take a look at what it could bring to the manufacturing industry.

What is virtual reality?

Before we begin, let’s first ask ourselves the following question: what is virtual reality exactly? We all have in mind, a helmet to put on the head and joysticks to hold in the hands. What about beyond that? Virtual Reality -or VR- is defined according to the Virtual Reality Society as: “the term used to describe a three-dimensional, computer-generated environment which can be explored and interacted with by a person. That person becomes part of this virtual world or is immersed within this environment and whilst there, is able to manipulate objects or perform a series of actions.”

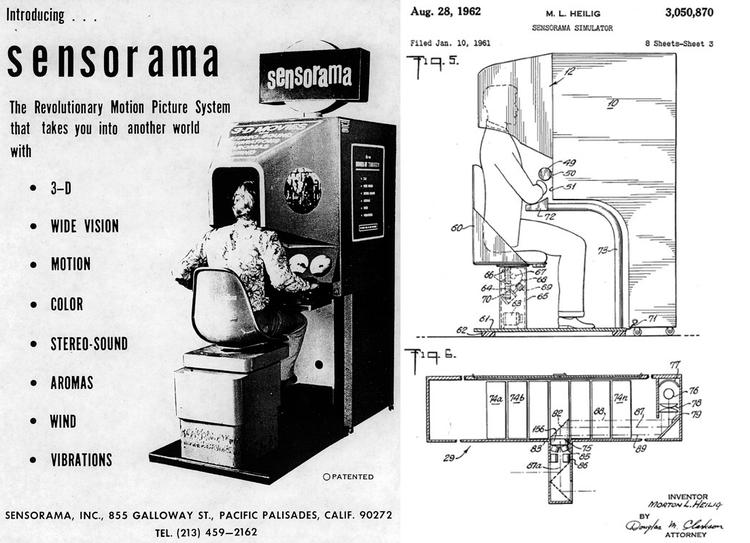

Although started to be exploited in the 90s, this breathtaking technology began in the 1950s with Morton Leonard Heilig. This pioneer wanted to build “the cinema of the future”. He contributed to the development of Sensorama, an arcade video game that was immersive – and impressive – for the time. It was actually possible to drive a motorcycle through Brooklyn streets while feeling the wind on your face, vibrations on your seat, with a 3D view and the add of smells for more immersion.

Image: realite-virtuelle.com

VR technology is based on a connection between a real-world user and a created virtual environment with which it’s possible to interact. These interactions can range from a movement to a modification as if ultimately the real world and the virtual world were one.

How to implement virtual reality in the manufacturing industry?

Here’s the question we’re all interested in: what business-critical applications can virtual reality bring? The fields seem endless but let’s look at some main tracks together.

First and foremost, security is an area where virtual reality can greatly contribute. Thanks to more and more precise simulation making it possible to reproduce working simulations, the operator can for example reproduce potentially dangerous maneuvers. According to TestDrivenTV, Automotive giant Ford, a company leading the way in VR integration, has reduced employee injuries by 70 percent. A figure that could bring more companies to invest in virtual reality. Another interesting possibility is that you can identify problems before they impact production by creating a digital twin. Virtual reality can also reduce training time for your operators with a virtual training so you’ll be sure people are fully prepared for real-world applications.

To finish, VR allows creating a way better product that matches the expectations of the consumers. Engineers and designers can go through the different product’s phases without having to produce it. It becomes actually easy and quick to modify the product or improve any aspect of it with a real-life environment. Everyone will tell you, offering a better customer experience compared to your competitors can significantly increase your market share.

It won’t be a surprise if, during the next years, the industrial machine industry or even an inspection for used equipment, for example, require the use of virtual reality.

Thank you for reading our articles, stay informed about the industrial world and Exapro by following us on Exapro Hub, Facebook, Twitter and LinkedIn.