Nowadays, almost every household owns a printer which is used to print out study materials, copy pages and scan documents. Industrial printing machines, however, are capable of performing specific actions on a much larger scale. Certain categories of machines handle label printing, while others specialize in photo and press printing or even offset printing. Before speaking of 5-colour offset printing machines in greater details, let’s clarify what is offset printing in general.

Nowadays, almost every household owns a printer which is used to print out study materials, copy pages and scan documents. Industrial printing machines, however, are capable of performing specific actions on a much larger scale. Certain categories of machines handle label printing, while others specialize in photo and press printing or even offset printing. Before speaking of 5-colour offset printing machines in greater details, let’s clarify what is offset printing in general.

History of offset printing machines

Offset press or lithography press was first introduced to public in 1875 by an English scientist Robert Barclay. Lithography was commonly used to re-create art work. The printing process back in the end of the 19th century required flat printing plates commonly made of tin cans. Specially treated piece of cardboard covered the offset cylinder. The desired image was then transferred from the stone to metal surface. Later in the days, rubber was introduced instead of cardboard, which still belongs to the most commonly used material.

Offset printing technique

Now let’s fast forward through the 20th century and jump back to the modern age offset printing. In the modern printing process, one of the most important stages is prepress production. It is crucial to make sure all files are processed in the correct way during the printing process. Prepress production is usually done to avoid errors and bring down the printing costs. So before printing, all files should be converted into a proper CMYK color model (1,2,4,5,6,8 or more colors). The following step is to create press plates for each of the colors individually.

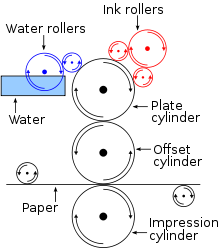

Offset printing process. Source: Wikipedia.

Offset printing process

There are several parts (systems) involved in the offset printing process.

- inking system

- dampening system

- plate cylinder

- offset cylinder

- impression cylinder

During the printing process, ink is distributed from the inking system to a sheet of paper in a few steps. The plate cylinder is covered with the offset plate. Inking and dampening systems working together deliver the ink and water to the offset plate. The plate cylinder further transfers the ink onto the blanket covering the offset cylinder. Impression cylinder then presses the paper against the offset cylinder, causing the ink to be transferred on paper.

Area of use of offset printers

Offset printing machines are widely used for printing of magazines, leaflets, brochures and books. As opposed to other printing methods, offset printing represents an economical way of printing large volumes of materials. To guarantee smooth running of printing process, modern offset printers use computer-to-plate systems that help to further increase printing quality. Offset printers come in various modifications: offset 1 color, offset 2 colors, offset 4 colors, offset 5 colors, offset 6 colors and offset printing machines with more than 8 colors.

Advantages of offset printing

- Offset printing technique allows to produce consistent high quality images. Images produced with an offset printer are sharp and clean, they also type with less effort than letterpress printing images. This happens due to the rubber blanket which is used in offset printers allowing closer contact with the printing surface.

- Offset printing is a low cost solution. It is the cheapest method to produce high quality images for commercial printing.

- Production of printing plates for offset printing is quick and easy. The printing plates have longer expiration period since there is no direct contact between the printing surface and the plate. If the printing plate is properly developed and the ink is optimized, it might achieve the run lengths of over a million imprints.

- In most types of offset printers, a metal blade is in control of the amount of ink which is transferred from the ink container to the fountain roller. The amount of ink delivered on the fountain roller can be adjusted with screw keys. An operator can simply adjust the screws to alter the gap between the fountain roller and metal blade. Thanks to the gap adjustment, the amount of ink applied on the fountain roller will be either increased or decreased. The amount of ink is directly linked to colour density on certain areas of the image. Majority of modern machines have the capacity to automatically operate the screw keys without any further manual adjustment. This feature enables higher precision of the end result.

Main attributes of offset printers

When looking to buy an offset printing machine, pay attention to the following technical attributes:

- Max sheet size (max paper length x width)

- Minimum sheet size

- Max print surface

- Print media format

- Format of rubber wrap