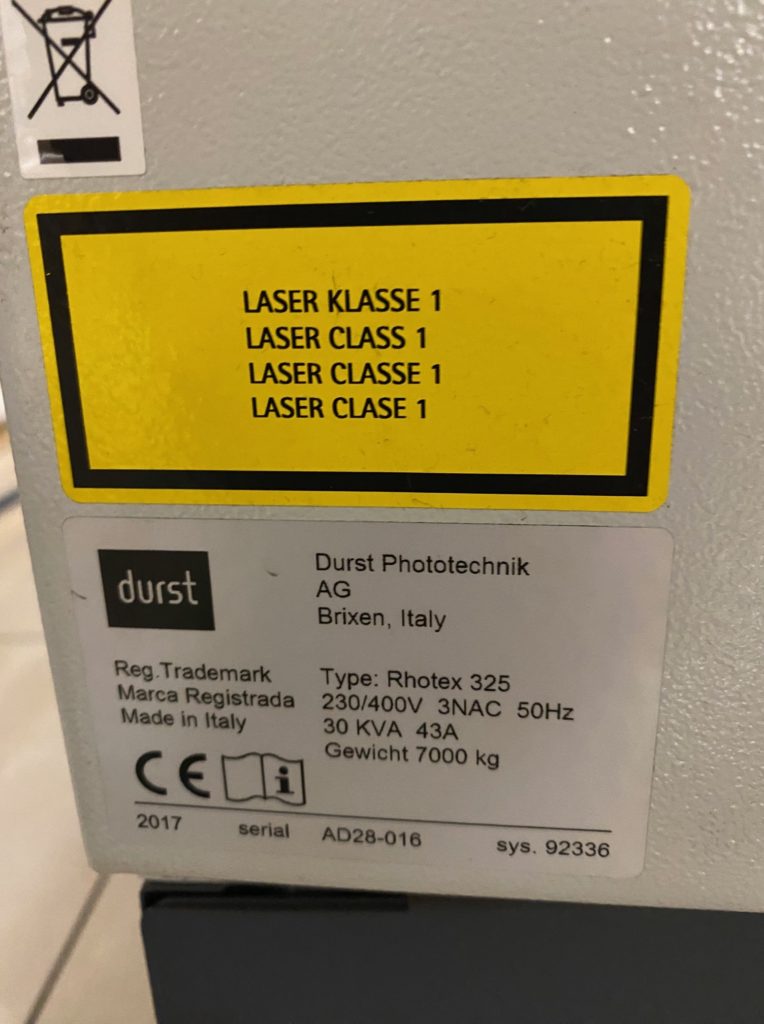

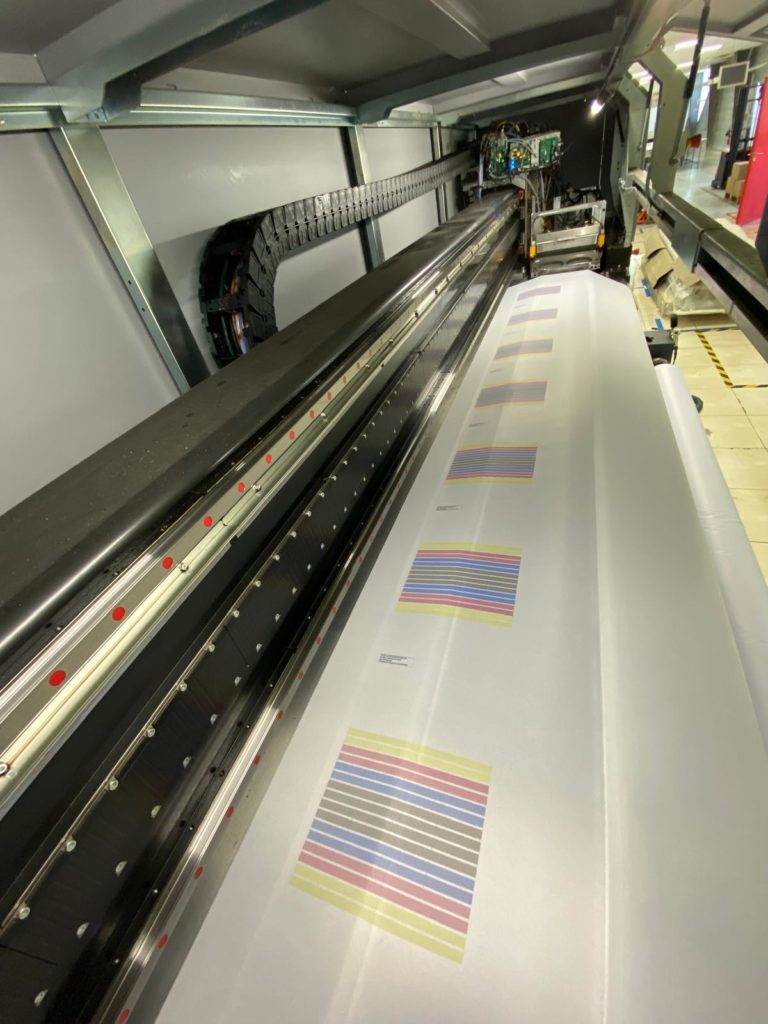

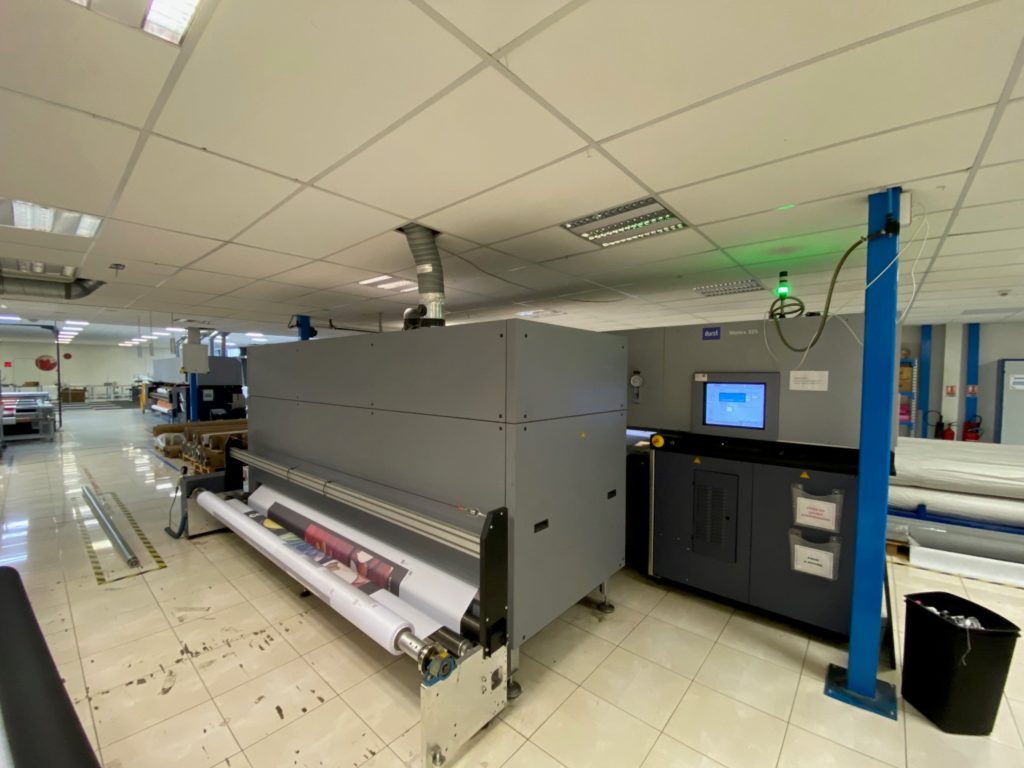

The Durst Rhotex 325, a 2017 model, is an industrial inkjet printer designed specifically for textile printing. Known for its exceptional performance, this printer is ideal for businesses seeking high-quality, eco-friendly printing solutions. This machine is visible in France, under production until the current owner can replace it with a new machine.

Overview of the Durst Rhotex 325

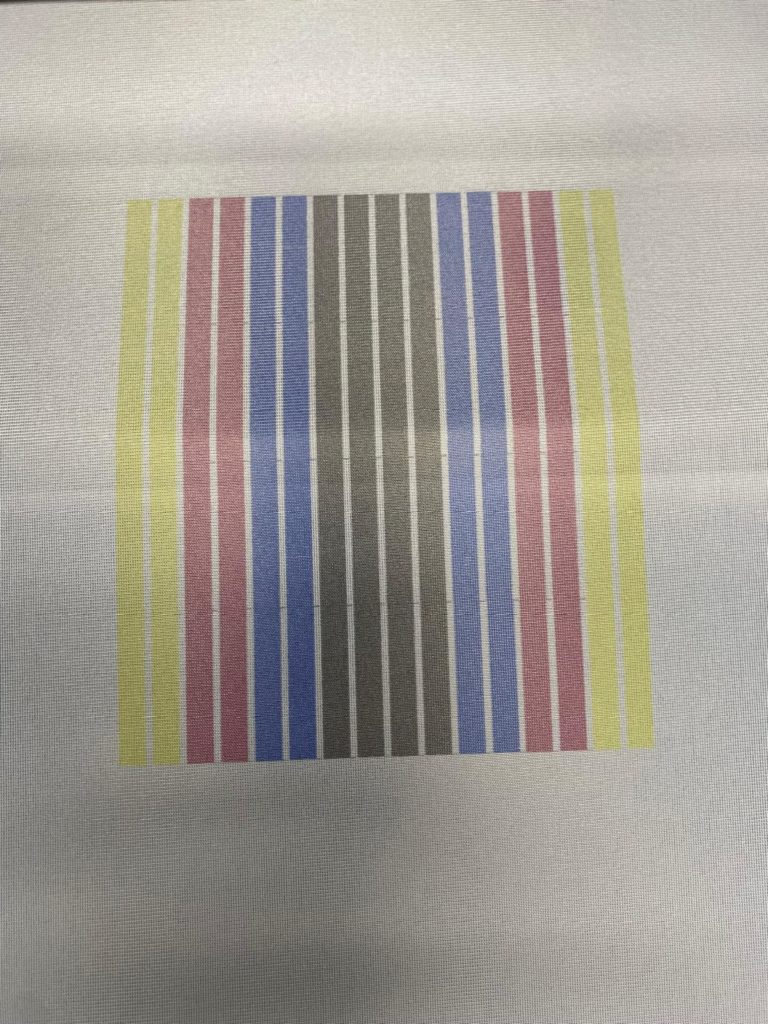

The Durst Rhotex 325 is a robust printing system that combines the best of both direct-to-textile and dye sublimation transfer printing. Designed to meet the demands of industrial textile printing, this machine offers unparalleled flexibility, allowing you to switch between different printing modes depending on the fabric and application requirements.

Key Features:

- Print Speed: Up to 140 m²/hour (4 passes), making it highly efficient for large-scale production.

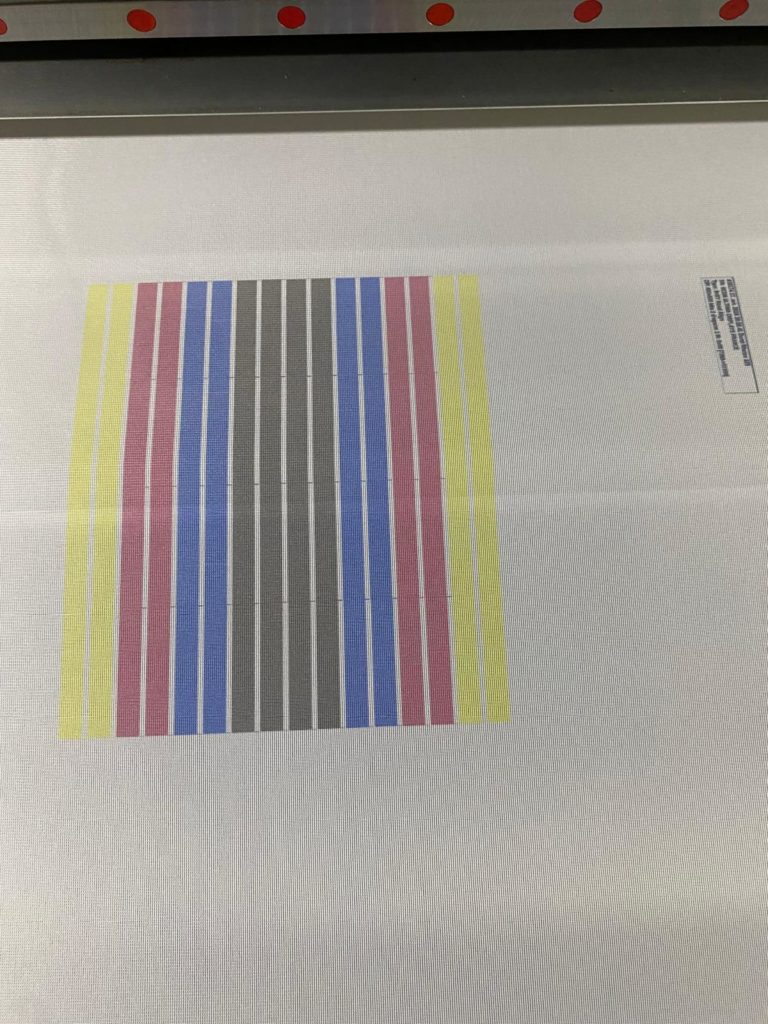

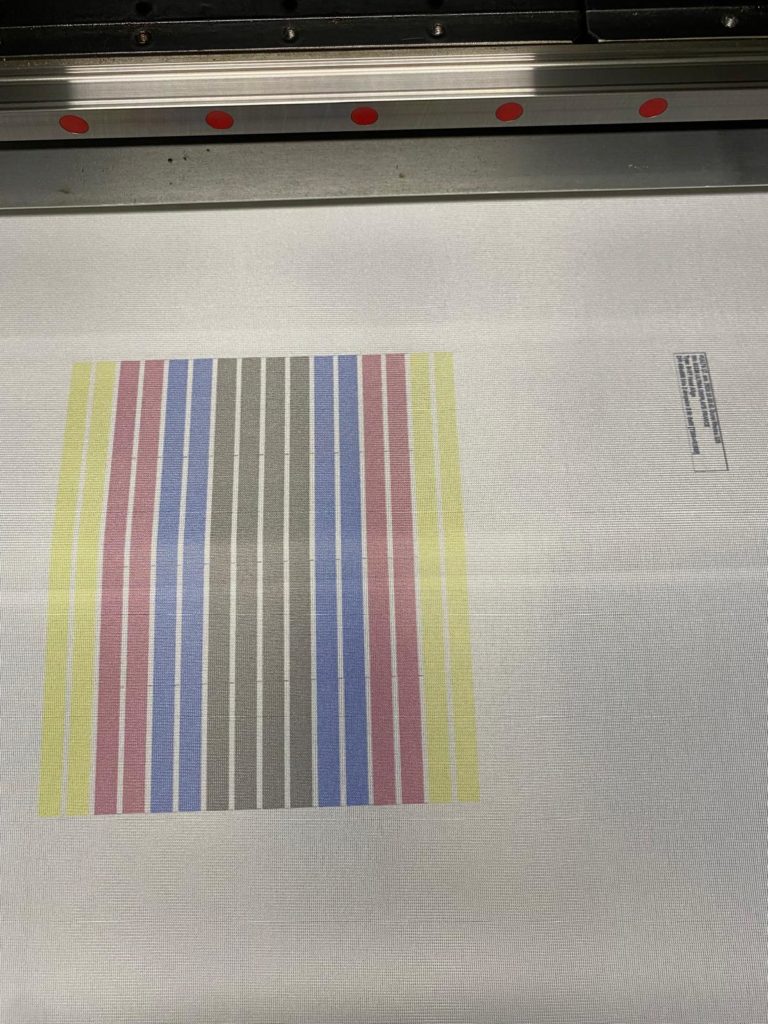

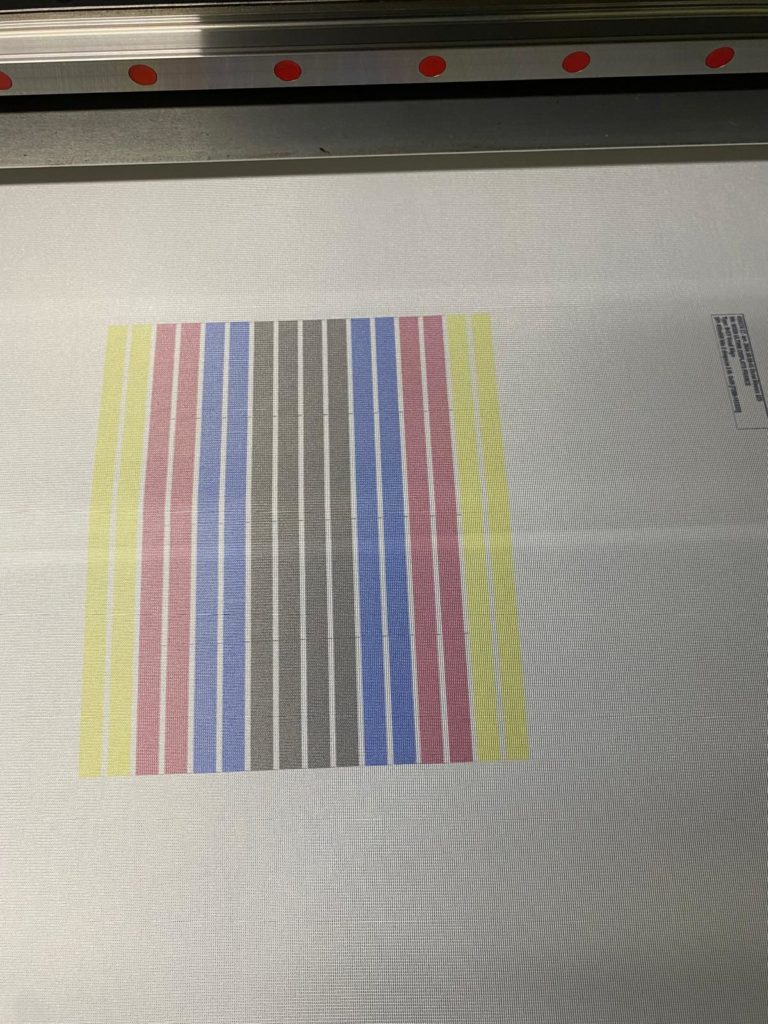

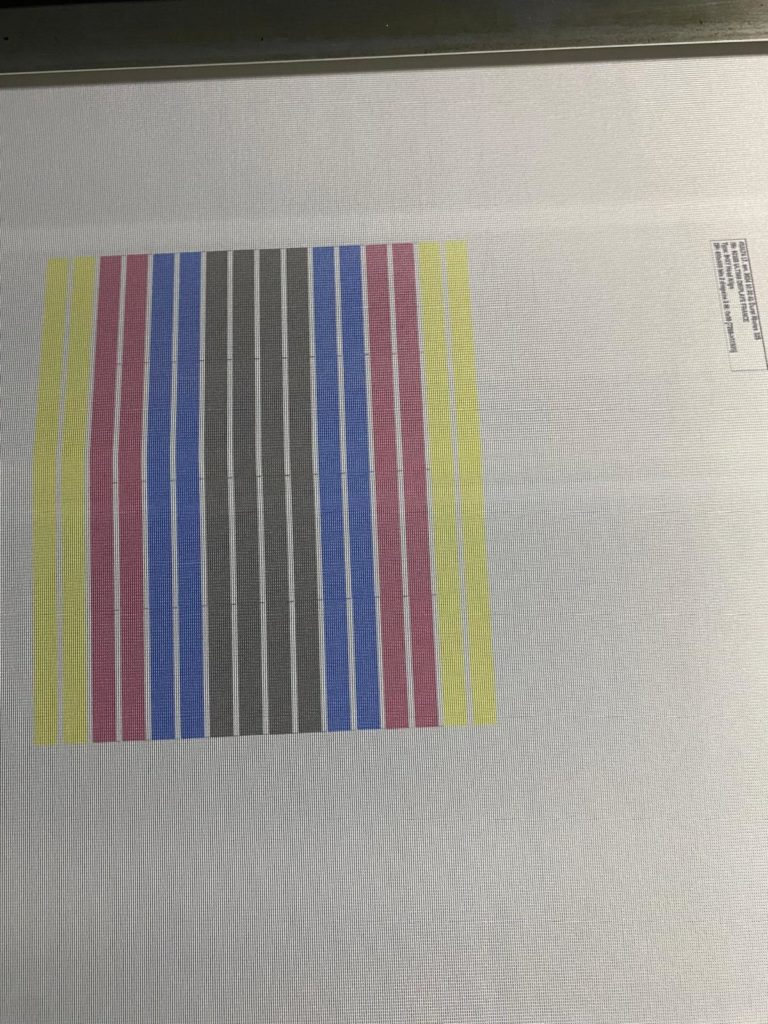

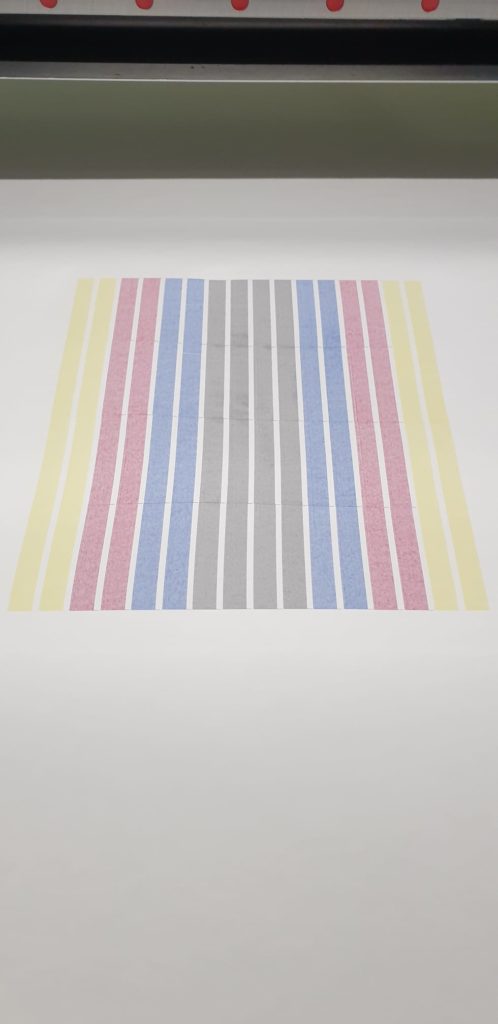

- Print Resolution: High-quality prints at 800×600 dpi.

- Eco-Friendly Inks: Utilizes water-based inks that are odorless, recyclable, and safe for the skin.

- Printing Width: Capable of handling fabrics up to 3200 mm wide.

- Versatility: Suitable for synthetic fabrics with at least 50% polyester content.

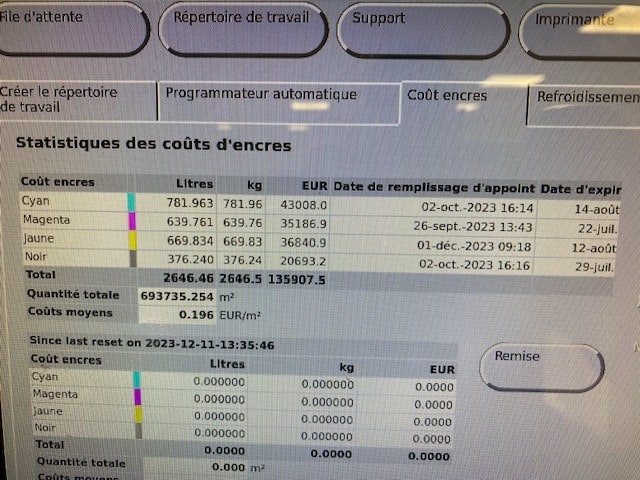

The Durst Rhotex 325 stands out in the market due to its ability to handle large printing jobs with ease. With a meter reading of 700 km² or 217,000 mL of printing, it has proven its reliability and durability in various industrial settings.

Technical Specifications

Here are the detailed technical specifications for the Durst Rhotex 325:

- Working Width: 3200 mm

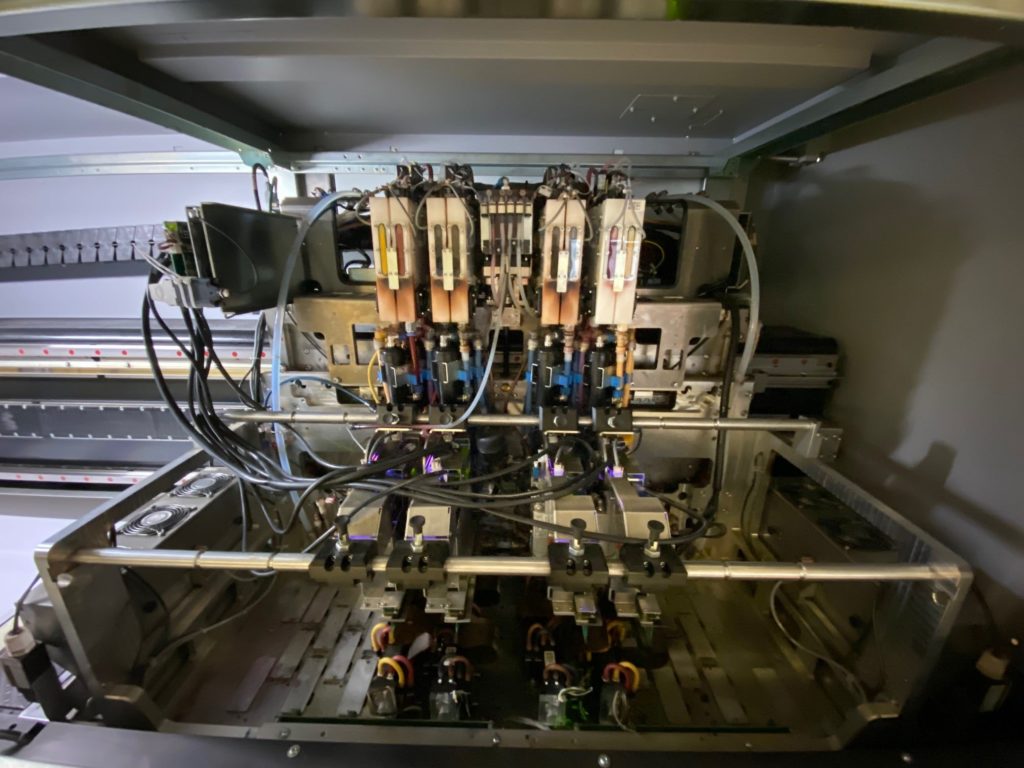

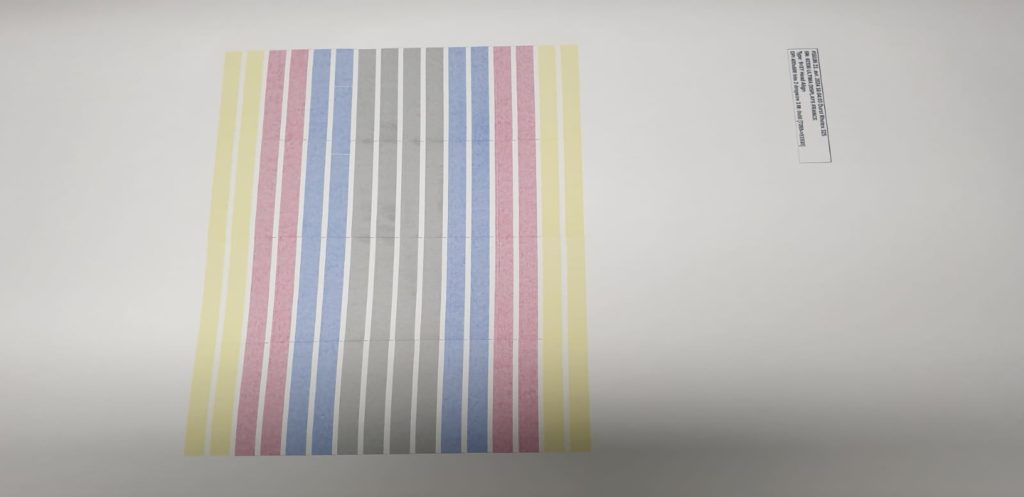

- Number of Colors: 4 (CMYK), with optional light cyan, light magenta, and light black spot colors

- Resolution: 800×600 dpi

- Ink Type: Water-based, odorless, environmentally friendly, skin-safe inks conforming to Oeko-Tex Standard 100

- Weight: 7000 kg

- Productivity: Up to 140 m²/hour

- Media Types: Synthetic fabrics (minimum 50% polyester)

- Maximum Roll Diameter: 400 mm (16 in)

- Maximum Media Thickness: 2 mm for textiles and 0.15 mm for transfer paper

- Status: Visible and operational

- Purchase Value in 2018: €350,000

Maintenance and Refurbishment Considerations

While the Durst Rhotex 325 is a highly capable machine, potential buyers should be aware of the maintenance and refurbishment costs associated with its upkeep. The following is a breakdown of the necessary work required to ensure the machine operates at its best:

Installation and Heavy Lifting Costs

- Heavy Lifters: To get the machine into the building, heavy lifters will be required, which adds an extra cost of €11,000.

- Installation by Durst: Professional installation and commissioning by Durst will incur an additional cost of €10,000.

Necessary Repairs and Replacements

- Media Bar Replacement: The media bar on the loading side is bent and will need replacement. This could cost around €1,500, including freight, based on typical Durst pricing.

- Ink Pumps and De-Gassers: The service report does not indicate any replacements for the ink pumps or de-gassers. These components are crucial for maintaining print quality and reliability. The cost for these parts alone is estimated at €6,000+.

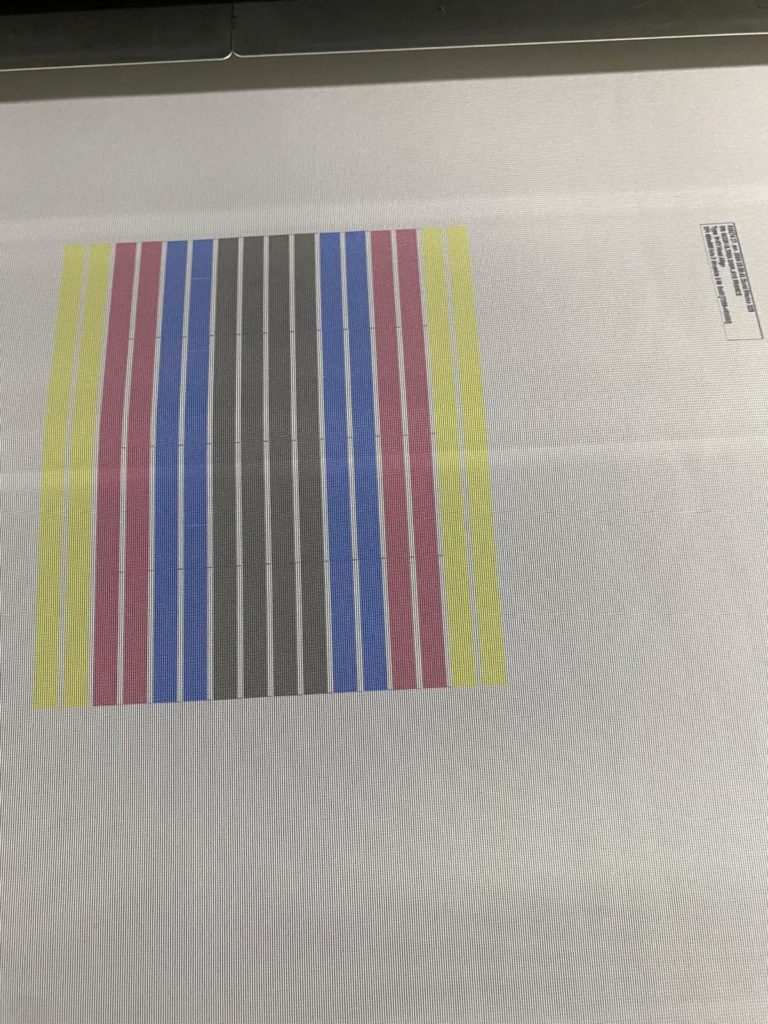

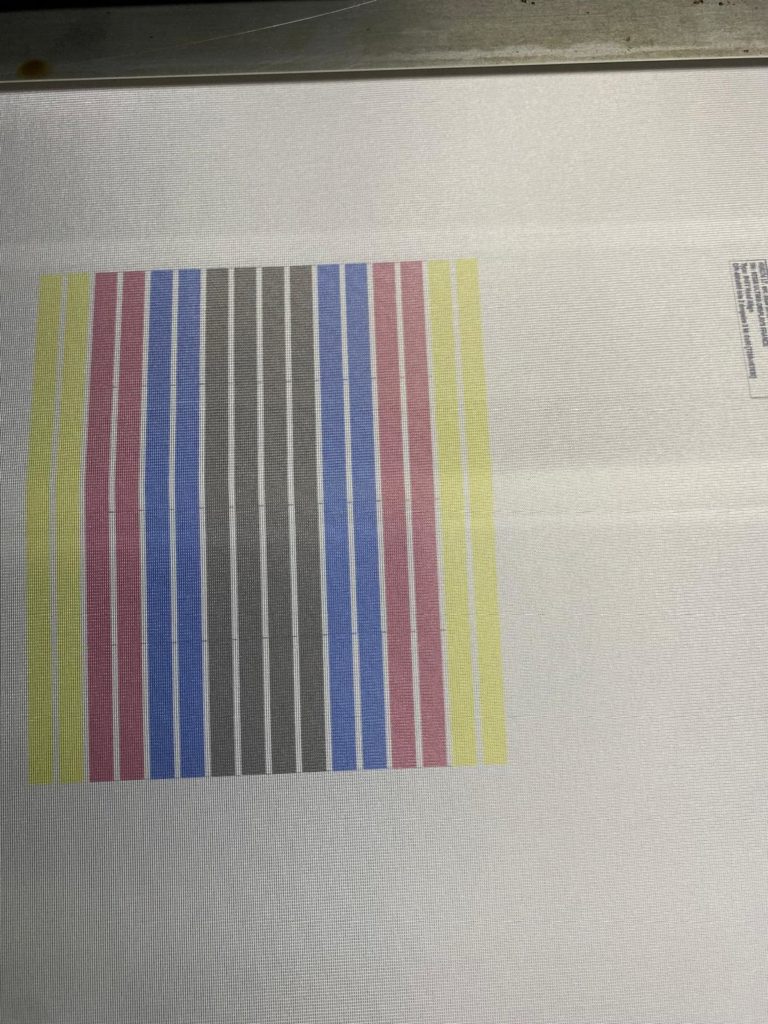

- Cyan Printhead Issues: There have been issues with the cyan printhead, which may require replacing up to four heads. This could add another €8,000-€9,000 to the refurbishment costs.

- Service Labor: The service work, which includes replacing parts and conducting thorough maintenance, will require at least 6-7 working days at a daily rate of €1,100. This brings the labor cost to around €7,000-€8,000.

Recent Refurbishment Experience

A recent refurbishment of a similar Rhotex 325 involved extensive work on the ink system, including replacing tanks, filters, hoses, pumps, de-gassers, and a fusion control card, as well as installing five new printheads. This comprehensive refurbishment cost €40,000. While this investment significantly enhances the machine’s performance, it highlights the potential costs involved in maintaining a Rhotex 325 to its optimal operating condition.

Why Choose the Durst Rhotex 325?

Despite the maintenance considerations, the Durst Rhotex 325 remains an outstanding choice for industrial textile printing. Its combination of speed, print quality, and environmental sustainability makes it ideal for businesses aiming to produce high-quality textile prints with minimal environmental impact. The ability to print directly onto fabric or via dye sublimation transfer adds a level of versatility that is hard to match.

Additionally, Durst’s commitment to innovation and customer support ensures that you will have access to the latest technological advancements and a reliable service network. The Rhotex 325 is not just a printer; it is a long-term investment in your business’s success.

The Durst Rhotex 325 is a powerful and versatile industrial inkjet printer designed for businesses that demand high-quality, eco-friendly textile printing solutions. While the machine requires some maintenance and refurbishment, the investment is well worth it for the performance and flexibility it offers. With proper care, the Rhotex 325 can continue to deliver outstanding results for years to come.

FAQs

1. What types of fabrics can the Durst Rhotex 325 print on?

The Durst Rhotex 325 is designed to print on synthetic fabrics that contain at least 50% polyester. It can handle a wide range of coated and uncoated polyester-based materials.

2. What is the maximum printing width of the Durst Rhotex 325?

The maximum printing width of the Rhotex 325 is 3200 mm, making it suitable for large-format textile printing.

3. How fast can the Durst Rhotex 325 print?

The Rhotex 325 can print at speeds of up to 140 m²/hour, depending on the print mode and fabric type.

4. What are the maintenance costs associated with the Durst Rhotex 325?

Maintenance costs can vary, but necessary replacements such as ink pumps, de-gassers, and printheads, along with labor, could cost upwards of €40,000.

5. Is the ink used in the Durst Rhotex 325 environmentally friendly?

Yes, the Rhotex 325 uses water-based inks that are odorless, recyclable, and conform to Oeko-Tex Standard 100, making them safe for both the environment and skin contact.