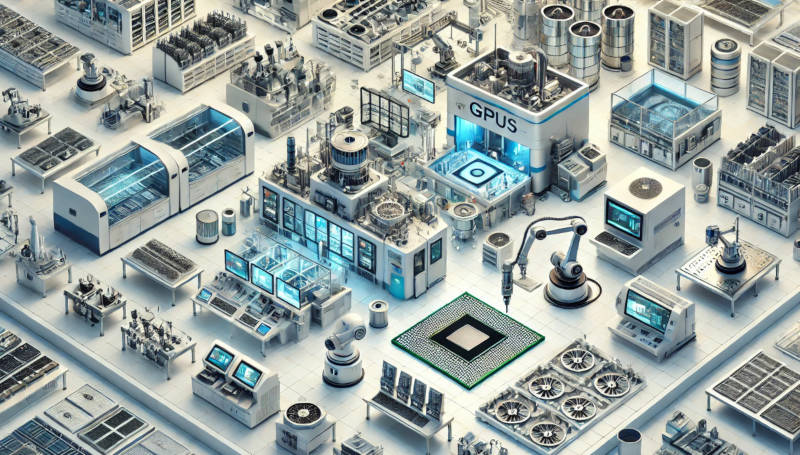

NVIDIA, a titan in the graphics processing unit (GPU) industry, has been at the forefront of technological advancements, driving innovations in AI, gaming, and professional graphics. Their success is built on a foundation of sophisticated machinery and meticulous manufacturing processes. Although NVIDIA outsources its chip fabrication to semiconductor giants like Taiwan Semiconductor Manufacturing Company (TSMC) and Samsung, a plethora of high-tech machines play crucial roles in their production.

Photolithography Machines

- Extreme Ultraviolet Lithography (EUV): Essential for creating the intricate patterns on silicon wafers, EUV lithography machines are manufactured by companies like ASML. These machines use ultraviolet light to etch minute details, enabling the production of extremely dense and powerful chips.

Etching Machines

- Reactive Ion Etching (RIE): RIE machines are employed to etch precise patterns into the silicon wafer using chemically reactive plasma. This technique is vital for creating the detailed circuitry in modern GPUs.

- Dry Etching: Unlike wet etching, dry etching uses gases or plasmas to remove material from the wafer, offering superior precision and control.

Deposition Machines

- Chemical Vapor Deposition (CVD): CVD machines deposit thin films of material onto the silicon wafer, forming the various layers needed in semiconductor devices.

- Physical Vapor Deposition (PVD): Used primarily for depositing thin metal films, PVD techniques involve vaporizing a material and condensing it onto the wafer surface.

Ion Implantation Machines

- Ion Implantation: This process involves bombarding the silicon wafer with ions to alter its electrical properties. Ion implantation machines are crucial for doping, which is the addition of impurities to control conductivity.

Chemical Mechanical Planarization (CMP) Machines

- CMP Machines: CMP machines are used to polish the wafer surface, ensuring it is smooth and flat. This is critical for subsequent layering processes to achieve uniformity and performance.

Wafer Inspection and Metrology Machines

- Scanning Electron Microscopes (SEM): SEMs provide detailed inspections of the wafer surface at a microscopic level, ensuring the accuracy and integrity of the patterns etched.

- Optical Inspection Tools: These tools are used to detect defects and irregularities on the wafer, ensuring that only high-quality chips proceed through the production line.

Packaging and Testing Machines

- Wire Bonding Machines: These machines connect the silicon chip to its package using fine wires, facilitating the integration of the chip into electronic devices.

- Flip-Chip Bonders: Flip-chip bonding involves connecting chips to their packages using solder bumps, allowing for higher performance and reliability.

- Automated Test Equipment (ATE): ATE is used to test the functionality and performance of the finished chips, ensuring they meet NVIDIA’s stringent quality standards.

Assembly Equipment

- Surface Mount Technology (SMT) Machines: SMT machines are employed in the final assembly process to mount components onto printed circuit boards (PCBs), forming the complete graphics card or device.

These machines are part of a highly automated and precise manufacturing process, ensuring that NVIDIA’s GPUs maintain their reputation for high performance and reliability. By leveraging state-of-the-art machinery and working closely with equipment manufacturers, NVIDIA continues to push the boundaries of what is possible in semiconductor technology.

NVIDIA’s Recent Success

NVIDIA’s innovation extends beyond just hardware. Their recent endeavors include the launch of the Blackwell platform, set to revolutionize computing with unprecedented performance enhancements. Collaborations with TSMC and Synopsys on computational lithography platforms are paving the way for next-generation semiconductor manufacturing, accelerating the development of AI factories and advanced data centers

NVIDIA’s strategic use of cutting-edge machinery in its chip manufacturing process is a testament to its commitment to innovation and quality. The partnership with leading semiconductor foundries and equipment manufacturers ensures that NVIDIA remains at the forefront of the GPU industry, delivering products that continue to define the future of technology.