Construction equipment uses powerful technology which requires many safety precautions. The sheer size of most of the machines requires the close attention of all workers involved, including operators, spotters, groundworkers and visitors. Absolute knowledge and control of the machine is priority number one for all people at work site.

Heavy machinery has the strength to build enormous things, but it also has a huge potential for damage. It is crucial to constantly think about safety while handling heavy equipment. The consequences can’t be taken back. The results can be any kind of incident or collision such as damaging the equipment; or in a worse case, injury or even fatality.

1. Qualified people and their periodical training

Operating heavy machinery is not an easy job. It is really essential to hire a person who is physically and emotionally suitable for the position. Operators and groundworkers should have a healthy respect for heavy machinery and its power. They have to have the most uptodate knowledge of every piece of the equipment, its purpose and usage. Workers should be also familiar with potential mishaps which could happen while using the construction machinery and also how to prevent them.

When a company hires a person, they must train them comprehensively, providing safety courses and introducing every single piece of the construction equipment. An employer has to be sure that these safety trainings are periodically reviewed. They need to be aware of the possibility that the employees will start using equipment in a daily routine and may forget the damage that could be done with the equipment.

Every year the safety regulation should be updated. That is why It is really important to repeat safety training regularly to avoid any kind of hazard. In the construction industry is necessary to invest in the human factor of training. All workers involved in the certain project need to know all the risks they take if they don’t follow the safety rules.

2. Zero zones

Zero zones or blind spots are areas which are not normally visible when sitting in the equipment. All workers in the construction site have to be familiar with these blind spots. There are several ways to avoid an incident such as hitting someone or something in a zero zone. First, use mirrors and communicate with your coworkers with a radio transmitter. The operators need to be attentive and physically check blind spots by climbing out of the machine. They have to be sure no one and nothing is around while operating the machine.

Knowledge of blind spots is important for groundworkers, too. When the operator starts moving the heavy equipment, groundworkers need to be sure they are not standing in or leaving anything in zones which are not easily visible from the operator’s view.

3. Communication between co-workers

People who work together in construction have to build strong communication skills. Radio transmissions are being used as a communication tool in most work sites. As the construction sites are generally very noisy, workers also use hands signals. Hands signals have to be familiar to all workers. It’s highly important not to ignore any signals given by coworkers. Keep your eyes open and stay alert to avoid missing any signals.

4. Highly visible and protective clothing

High visibility is a requirement in all construction sites. Iridescent, brightly-colored vests increase the visibility of people working around heavy machinery. This piece of clothing is absolutely essential for groundworkers and spotters to allow operators to see them easily.

Possible night work requires more visible elements to increase visibility in the dark. A helmet is also important to prevent injury caused by falling debris.

Steel-toed boots and protective gloves are also important in the prevention of injuries when using heavy equipment. Workers need to keep their protective gear clean and make sure there aren’t any holes or damage. This is mainly important when climbing on and off the machinery to avoid slipping.

5. Using seat belts

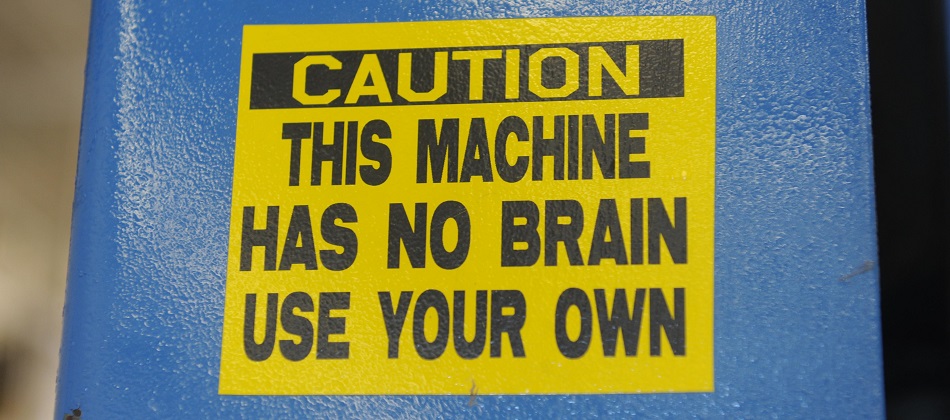

Using seat belts is an absolutely basic rule when operating equipment. Even though this tip seems to be obvious, at the same time is the most forgotten. It can be easily remembered by placing a sign such as “Don’t forget your seatbelt” at eye level of the operator in the machinery. This primary rule is a real lifesaver. The terrain in the construction site is unpredictable and the equipment is moving and shaking which can really throw the operator around. It is essential to make sure the operator is safely seated and belted. In case of rollover or back over, seat belts can save the life of the operator.

6. Proper loading

Every heavy machine has its limit of the weight and size that it can hold. Never overload a machine. Overloading can cause a rollover or back over which can have fatal consequences. Make sure the size and weight of the loaded material is not significantly higher than it should be to avoid damage to the machine or material itself.

While lifting and moving the load, an operator needs to be sure everyone is a safe distance away from the machine. Nobody should be walking under the suspended load, in the way of moving loads, or standing in the blind spot or zero zones. Do not hesitate to jump off the equipment and physically check that the area around the load is clean and clear. Workers have to simply know the area and follow safety regulations.

Loading should be done only on level ground to avoid any incidents or rollovers.

7. Using equipment only for their intent purpose

Make sure the equipment is used only for its intended purpose. Every single piece of equipment was designed to perform a specific task. Do not try its capacity over its purpose. It means not to carry anything or anyone where they weren’t designed to be. Don’t jump on or off the equipment from a different way then intended.

8. Pre-work check

Do not hesitate to walk around and physically check the surroundings of the machinery before starting work. Be sure there is no fluid under or around the machinery which could be a sign of damage of the equipment. The inspection of the machine itself cannot be ignored either. Inspect the tires, tracks and components. Be sure there are no factors of a damage on any piece of the equipment. Check fluid levels and tire pressure to avoid any possible malfunction of the machinery.

The inspection of the machine and its surroundings should be done at least once a day before starting the machine. Better to practice the inspection even several times per day to be sure all is in the best working order.

9. Climb on and off the equipment properly

This rule may sound not as important as others. But statistic says the most common injuries in construction site are caused by getting in and out of the machine incorrectly. Here is a piece of advice to avoid injuries while entering and exiting equipment.

When leaving the equipment, use the protective gloves to prevent slipping. Placing feet properly on the intended place is crucial. Always use the three-point contact. These three points will help with the stability and prevent falls.

Make sure your physical predispositions are suitable for the equipment. If needed, do not hesitate to ask for an extra handle to avoid any injuries.

10. Clean working area

The clean working area is necessary for safe work. Make sure no piece of wood, steel or other surplus of construction material is around. Oil lakes and other fluid from the machines are also dangerous.

Having a clean working area also involves cleaning the inside of the equipment. Do not take any unnecessary equipment which can move or fall down into the machinery as it could cause an injury or interfere with the continuation of the work.

11. Putting away equipment

Make sure the equipment is left properly. Park only on level ground to avoid any unwanted movements and rollovers. Remove the key to prevent any unexpected startups. Before leaving make sure all motions are stopped. Never leave the machinery with an engine on. The pressure of the hydraulic controls should be relieved. And do not forget to jump off the equipment from the correct place while using the three-point contact rule.

12. Recognition of worker’s physical and emotional limits

Every single person is different. They have different limits and capacities of their physical and emotional sides. Operating heavy equipment requires high attention and focus. A worker should have a clean bill of health and a clear understanding of his limits. An operator cannot be shy about asking for help and admitting that some tasks are beyond his limits. It is better to think twice than cause an incident which could have been avoided.

Have in mind that some medications might have a side effect of drowsiness and have warning against operating heavy machinery. Heed these warnings! It is essential not to push yourself over your health limits and knowing when to ask for a help.

Emotion is a strong moving power in each of us. Be sure anger, sadness or any other emotion will not influence your performance when using construction machinery.

13. Have a safety conversation before each project

Here is the last tip of the article. It is not used in all companies but it is a great way to go the extra mile for a safe workplace. Holding a safety meeting before each new project or operation could prevent already known and also new incidents that could occur. Meet with supervisors, operators, spotters and groundworkers to talk about possible actions and precautions. This is a great way to avoid any incident in the most effective way.

This safety guidance is a summary of the most essential tips to have in mind while operating heavy machinery. It is a basic standard which can be subsequently expanded and modified to any kind of construction project.